|

|

|

|

|

|

|

|

|

|

|

The installation of ALMATHERM Polypropylene Random Copolymer pipes is similar to that of metal pipes. The only point is that expansion characteristics of this material must be taken into consideration in the design and calculations.

PP-R pipes can be installed on or in the walls. The unit weights of these pipes and fittings are 17 times smaller than metal pipes.

Installation of PP-R pipes is more practical, easier, quicker, cleaner and cheaper. If these pipes are laid in open area, then in the project designing stage, an axial motion compensation must be calculated and considered. In case the direction of expansion can not be directed into one way then free bending pieces or pieces with shape must be used.

In the sleeve joint points plastic units must be used in order not to make any damage on the pipe surface.

|

|

|

|

Compansation of expansion in pipe line.

|

|

|

|

In the figures below the application of fixed points are presented. When forming the fixed points, the extra forces like Weight of the pipe, curcilation in the medium and the additional loads which cause linear expantion in the pipe length must be considered.

|

|

|

|

Fixed supports prevent any movement of the pipe by fixing it at some points. Fittings are used in creating fixed points. Fixing power of the fixed supports must be stronger than the sliding supports. Fixed supports must not be installed at bending parts and the direction changes must be done in the pipe itself. In between the fixed supports some arrangements must be done to compensate any potential elongation or shrinkage in the pipe length.

|

|

|

|

|

|

|

|

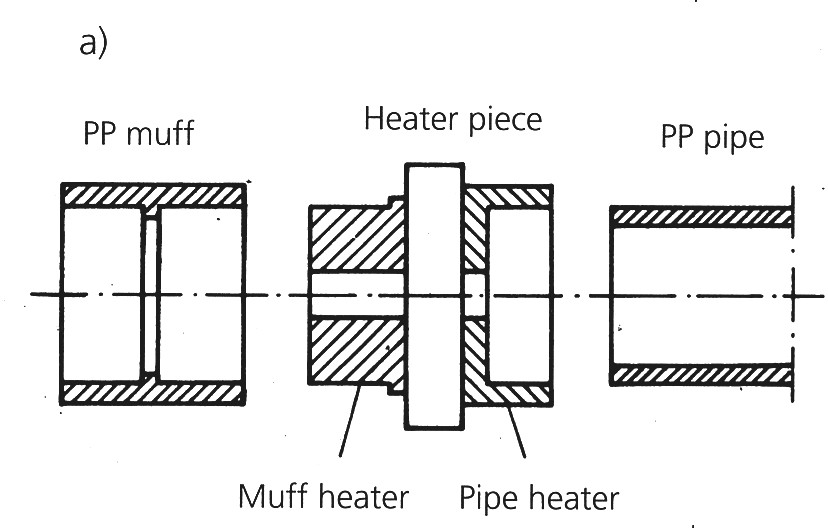

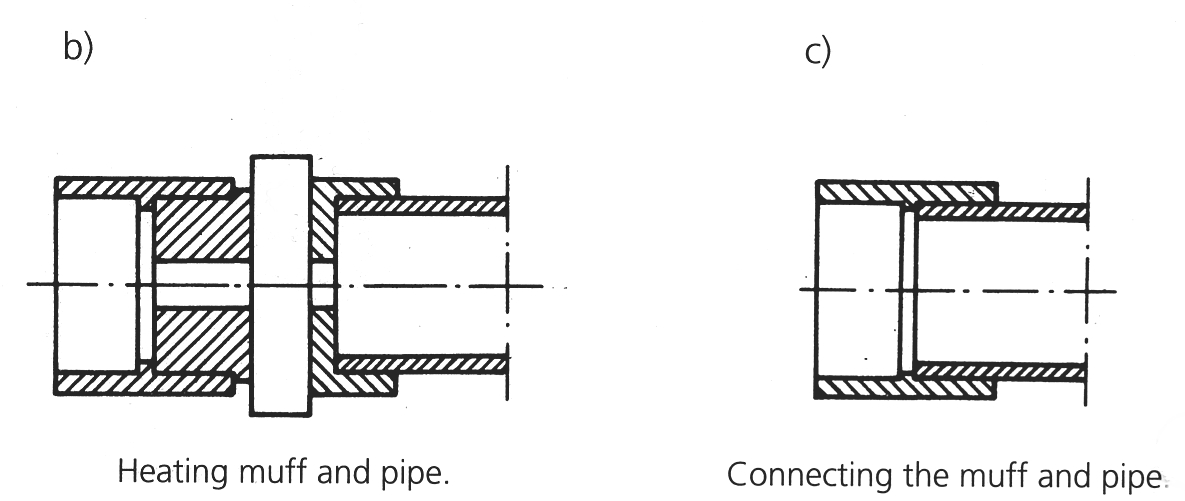

Welding Technique:

For straight pipes having length more than 5 meters, to compensate the expansion an expansion piece must be used. Crossover should be used at the junctions of the laid pipes. For crossover piece 20mm, 25mm and 32mm sizes are available.

The quality of each installation system ultimately depends on the tightness, stability und lifetime of its connections. The homogeneous connection of ALMATHERM pipes by fusion welding by means of welding sockets gives us an absolutely safe pipe connection and guarantees utmost operational safety. It takes only a few seconds to make a connection by fusion welding process. After a couple of minutes already, the welded joint cools down sufficiently and can be fully loaded.

Cut the pipe and heat it and the fittings with a welding device. Then put both parts straight together, without twisting. All done … Simply with little effort and perfect results. The welding process is safe because the properly heated parts of the polypropylene creates a homogeneous connection.

Guidelines for Welding Process

- Choose the proper heating piece and amount it on the welding machine.

- Switch the welding device on. Control lamp and switch lamp will lit. When ready, control lamp goes off, then it means that the welding temperature (260°C +/- 10°C) had been reached.

- Place the pipe end and the piece to be welded on the welding machine properly.

- If welding devices, pipes and fittings are dirty, clean them with a cloth and a alcohol-water solution.

- When heated up after a few seconds, remove pipe and form piece from welding machine and connect the two heated ends applying a little pressure without twisting. Let it cool down for a few seconds.

The processing times, like heating, fusion and cooling, are shown in the table below. Please keep in mind, that different pipe diameters need different processing times. The welded unions have to be kept in a tight condition during the cooling down.

|

|

|

|

|

Outer dim. of pipe (mm)

|

Heating up (sec.)

|

Processing (sec.)

|

Cooling period (min)

|

Manual Welding machine

|

|

16

|

5

|

4

|

2

|

|

20

|

5

|

4

|

2

|

|

25

|

7

|

4

|

2

|

|

32

|

8

|

6

|

4

|

|

40

|

12

|

6

|

4

|

|

50

|

18

|

6

|

4

|

|

|

|

|

|

|

|

|

|

|

Mounting of Pipes & Fittings:

After cutting the pipe to the desired length, you can make all connections by fusion welding machine economically and easily. Since PP-R pipes are light and flexible, their transportation and installation is easier.

Under the tough conditions at site, the system proves its quality for top safety level. ALMATHERM installation system is using advanced techniques without giving up habitual parts like tees and fitting which, by means of the fusion welding process make your installation just like one piece, from the basement up to the roof. The reliability of the installation of the pipes depend on the quality of the sub-materials and the perfection of welding operation. Perfect quality and high efficiency with ALMATHERM products are your key to success.

There are two main connection methods:

A) Threaded fittings: Its connection method is the same as in galvanized pipe installations.

B) The connection realized by fusion welding:

- two edges of pipes and fittings are heated by welding machine and connected to each other.

- in this system electro fusion technique is done by using the right fittings which was produced for this purpose.

The principle of muff welding is shown in the figure, as below:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

© copyright 2017: almanit sanitary gmbh, Hamburg, Germany

All rights reserved. Reproduction in whole or in part without the written permission of the copyright owner is prohibited. |

|